MANUFACTURING

All it takes to make

the perfect cartridge

Ceramics cartridges are the heart of the faucet, ceramic discs are the heart of the cartridge. All parts of Quore cartridges are produced internally, extreme care is dedicated to the discs where it’s essential to have complete control of every step of production to be sure of a finished product that will ensure precision, durability and reliability.

It begins with the selection of the best raw materials made cohesive through cold forming, the sintering process in high temperature ovens, lapping, cleaning, drying and finally surface inspection.

Seals are also produced internally, including the mixing of materials, stamping and vulcanization. And so is the molding and stamping for the shells and the machining of brass rods for spindles.

No third part suppliers of components are involved, only the best selection of raw materials purchased from all over the world enter the factory.

Cartridge manufacturing steps

1 → Dry pressing

Dry pressing using high grade german raw material

2 → Sintering

The material is hardened during the sintering process, 18 hours at 1650°C

3 → Defects check

Any defective disc that is spotted with this method is removed from the production line and discarded

4 → Double side grinding

Discs are ground on both sides

5 → Polishing

Discs are polished, at least 25 minutes on the bottom and 18min on the top surface

6 → Second polishing

More polishing for the surfaces

7 → Ultrasonic cleansing

Discs are cleaned through ultrasonic waves

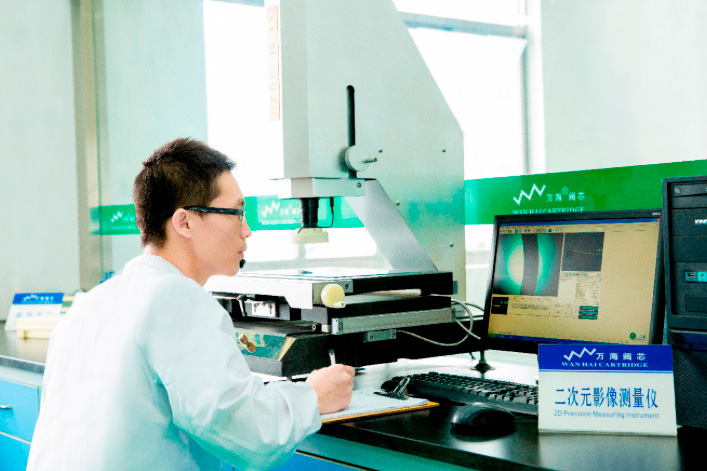

8 → Ceramic disc inspection

Ceramic discs are inspected by an operator that checks their suitability for the next step

9 → Silicon material vulcanization

The compound is produced

10 → Material preforming

The plastic material is shaped by preforming machines

11 → Silicon vulcanization

Gaskets are vulcanized

12 → Deburring

Gaskets are scraped and cleaned

13 → Inspection

Parts are inspected for the next step

14 → Injection

Cartridges plastic shells are injected

15 → Assembly

Ceramic cartridges parts are assembled, with 7 workers per line

16 → Dynamic pressure test

Dynamic pressure test are performed on the cartridges

17 → Leakage test

Each cartridge is tested for leakage before items packing

18 → End product

Quore ceramic cartridges are ready for shipping